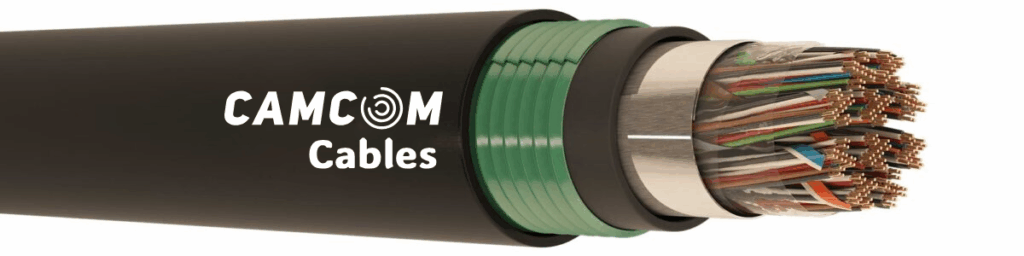

A-2YSF(L)2Yb2Y Outdoor Telephone Cable

Product Code: PDF-PAbP

| 1 – Conductor | : | Electrolytic annealed solid copper (CCITT Yellow Book Vol. III-2-G.541 B article, IEC 28 and ASTM B 3). |

| 2 – Insulation | : | Color coded solid polyethylene insulation (BS 6234 Type 03 – ASTM D 1248). |

| 3 – Stranding | : | Star quads or pairs are assembled into 10 pairs units. Groups having 25, 50 or 100 pairs are stranded together. |

| 4 – Filling Compound | : | Cable core is filled with a special jelly filling compound to avoid the water leakage into air spaces. |

| 5 – Wrapping | : | A non-hygroscopic and dielectric polyester tape is applied on the cable core longitudinally or helically. |

| 6 – Filling Compound | : | Secondary jelly filling is applied between wrapping and screen in order to provide waterproofness. |

| 7 – Screen | : | Both sides are coated with copolymer coated flat aluminum tape over cable core longitudinally for screening. |

| 8 – Inner Jacket | : | Linear low-density or medium-density, UV resistant black polyethylene inner jacket (ASTM D 1248). |

| 9 – Bedding | : | Special tape is applied between inner jacket and armor. |

| 10 – Armor | : | Two helically laid galvanized steel tape is applied to increase the mechanical resistance of the cable. |

| 11 – Outer Jacket | : | Linear low-density or medium-density, UV resistant black polyethylene outer jacket (ASTM D 1248). |

| 1 – Conductor | : | Electrolytic annealed solid copper (CCITT Yellow Book Vol. III-2-G.541 B article, IEC 28 and ASTM B 3). |

| 2 – Insulation | : | Color coded solid polyethylene insulation (BS 6234 Type 03 – ASTM D 1248). |

| 3 – Stranding | : | Star quads or pairs are assembled into 10 pairs units. Groups having 25, 50 or 100 pairs are stranded together. |

| 4 – Filling Compound | : | Cable core is filled with a special jelly filling compound to avoid the water leakage into air spaces. |

| 5 – Wrapping | : | A non-hygroscopic and dielectric polyester tape is applied on the cable core longitudinally or helically. |

| 6 – Filling Compound | : | Secondary jelly filling is applied between wrapping and screen in order to provide waterproofness. |

| 7 – Screen | : | Both sides are coated with copolymer coated flat aluminum tape over cable core longitudinally for screening. |

| 8 – Inner Jacket | : | Linear low-density or medium-density, UV resistant black polyethylene inner jacket (ASTM D 1248). |

| 9 – Bedding | : | Special tape is applied between inner jacket and armor. |

| 10 – Armor | : | Two helically laid galvanized steel tape is applied to increase the mechanical resistance of the cable. |

| 11 – Outer Jacket | : | Linear low-density or medium-density, UV resistant black polyethylene outer jacket (ASTM D 1248). |