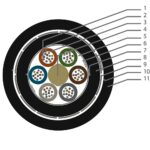

1 – Optical fiber core ¹

2 – Waterproof thixotropic jelly

3 – PBT Tube

4 – Non-metallic central strength member (FRP)

5 – Water-swellable yarn

6 – Core Wrapping (Water-swellable Tape)

7 – Ripcord

8 – UV resistant polyethylene (LLDPE) black inner jacket.

9 – Non-metallic strength member (Glass yarn)

10- Ripcord

11- UV resistant polyethylene (HDPE) black outer jacket

| Part Number |

Core Type |

Count Fiber |

Count Tube |

Count Filler |

Diameter Tube(mm) |

FRP Diameter (mm) |

Cable Diameter (mm) |

Cable Weight(kg/km) |

| 3.243.2.6.1.0900.0.1002 |

SM G.652.D |

2 |

1 |

5 |

2,05 |

2,2 |

12,5 |

124 |

| 3.243.2.6.1.0900.1.1004 |

SM G.652.D |

4 |

1 |

5 |

2,05 |

2,2 |

12,5 |

124 |

| 3.243.2.6.1.0900.0.1004 |

SM G.652.D |

4 |

2 |

4 |

2,05 |

2,2 |

12,5 |

125 |

| 3.243.2.6.1.0900.1.1006 |

SM G.652.D |

6 |

1 |

5 |

2,05 |

2,2 |

12,5 |

124 |

| 3.243.2.6.1.0900.0.1006 |

SM G.652.D |

6 |

3 |

3 |

2,05 |

2,2 |

12,5 |

125 |

| 3.243.2.6.1.0900.1.1008 |

SM G.652.D |

8 |

1 |

5 |

2,05 |

2,2 |

12,5 |

124 |

| 3.243.2.6.1.0900.2.1008 |

SM G.652.D |

8 |

2 |

4 |

2,05 |

2,2 |

12,5 |

125 |

| 3.243.2.6.1.0900.0.1008 |

SM G.652.D |

8 |

4 |

2 |

2,05 |

2,2 |

12,5 |

126 |

| 3.243.2.6.1.0900.1.1012 |

SM G.652.D |

12 |

1 |

5 |

2,25 |

2,2 |

13,2 |

136 |

| 3.243.2.6.1.0900.2.1012 |

SM G.652.D |

12 |

3 |

3 |

2,05 |

2,2 |

12,5 |

125 |

| 3.243.2.6.1.0900.0.1012 |

SM G.652.D |

12 |

6 |

0 |

2,05 |

2,2 |

12,5 |

128 |

| 3.243.2.6.1.0900.1.1016 |

SM G.652.D |

16 |

2 |

4 |

2,05 |

2,2 |

12,5 |

124 |

| 3.243.2.6.1.0900.0.1016 |

SM G.652.D |

16 |

4 |

2 |

2,05 |

2,2 |

12,5 |

126 |

| 3.243.2.6.1.0900.0.1020 |

SM G.652.D |

20 |

5 |

1 |

2,05 |

2,2 |

12,5 |

126 |

| 3.243.2.6.1.0900.1.1024 |

SM G.652.D |

24 |

2 |

4 |

2,25 |

2,2 |

13,2 |

136 |

| 3.243.2.6.1.0900.3.1024 |

SM G.652.D |

24 |

3 |

3 |

2,05 |

2,2 |

12,5 |

125 |

| 3.243.2.6.1.0900.2.1024 |

SM G.652.D |

24 |

4 |

2 |

2,05 |

2,2 |

12,5 |

125 |

| 3.243.2.6.1.0900.0.1024 |

SM G.652.D |

24 |

6 |

0 |

2,05 |

2,2 |

12,5 |

127 |

| 3.243.2.6.1.0900.0.1032 |

SM G.652.D |

32 |

4 |

2 |

2,05 |

2,2 |

12,6 |

125 |

| 3.243.2.6.1.0900.0.1036 |

SM G.652.D |

36 |

3 |

3 |

2,25 |

2,2 |

14,2 |

156 |

| 3.243.2.6.1.0900.1.1036 |

SM G.652.D |

36 |

6 |

0 |

2,05 |

2,2 |

12,5 |

126 |

| 3.243.2.6.1.0900.1.1048 |

SM G.652.D |

48 |

4 |

2 |

2,25 |

2,2 |

13,2 |

137 |

| 3.243.2.6.1.0900.0.1048 |

SM G.652.D |

48 |

6 |

0 |

2,05 |

2,2 |

12,6 |

128 |

| 3.243.2.6.1.0900.0.1060 |

SM G.652.D |

60 |

5 |

1 |

2,25 |

2,5 |

13,2 |

137 |

| 3.243.2.6.1.0900.0.1064 |

SM G.652.D |

64 |

8 |

0 |

2,05 |

2,7 |

14,2 |

157 |

| 3.243.2.6.1.0900.0.1072 |

SM G.652.D |

72 |

6 |

0 |

2,25 |

2,5 |

14,2 |

157 |

| 3.243.2.6.1.0900.0.1096 |

SM G.652.D |

96 |

8 |

0 |

2,25 |

2,7 |

17,6 |

190 |

| 3.243.2.6.1.0900.0.1120 |

SM G.652.D |

120 |

10 |

0 |

2,25 |

2,7 |

17,6 |

209 |

| 3.243.2.6.1.0900.0.1144 |

SM G.652.D |

144 |

12 |

0 |

2,25 |

2,7 |

18,5 |

259 |

| Test Standard |

Specified Value |

Acceptance Criteria |

| Maximum Installation Tension ² |

IEC 60794-1-2-E1 |

1.5 x W(N), min. 2700 N |

Fiber strain ≤ 0.33% |

| Maximum Operation Tension |

IEC 60794-1-2-E1 |

0.5 x W(N), min. 900 N |

Δα ≤ 0.05 dB, No fiber strain |

| Crush Strength |

IEC 60794-1-2-E3 |

4000 N / 100 mm, max. 15 min. |

Δα ≤ 0.05 dB, No damage |

| Impact |

IEC 60794-1-2-E4 |

10 Nm, 3 impacts, R= 300 mm |

Δα ≤ 0.05 dB after the test |

| Torsion |

IEC 60794-1-2-E7 |

1 m. 100N, +/- 180°, 10 cycles |

Δα ≤ 0.05 dB, No damage |

| Repeated Bending |

IEC 60794-1-2-E6 |

R=20x D, 100 N, 35 cycles |

No damage |

| Bending Radius |

IEC 60794-1-2-E11 |

R=20x D, 4 turns, 3 cycles |

Δα ≤ 0.05 dB, No damage |

| Temperature Cycling |

IEC 60794-1-2-F1 |

-20°C to +70°C |

Δα ≤ 0.05 dB/km |

| Waterproofness |

IEC 60794-1-2-F5B |

Sample= 3 m, water column= 1 m |

No water leakage in 24 hours. |

| Minimum Bending Radius |

| Operation |

20 x cable Ø |

| Fixed |

15 x cable Ø |

|

Temperature Range |

| Storage |

-40°C to + 70°C |

Installation |

-30°C to +60°C |

| Transport |

-40°C to + 70°C |

Operating |

-40°C to +70°C |

| Marking |

Camcom – Signaling Innovation – Date of Manufacture – Fiber Count and Type – Length Marking |

| Packing |

Wooden drum with protection |

| Delivery Lengths |

2 km, 4 km ± %5 tolerance |